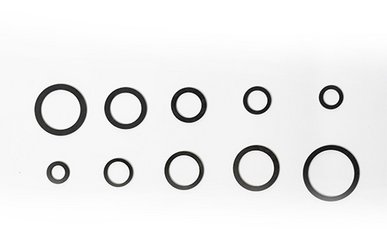

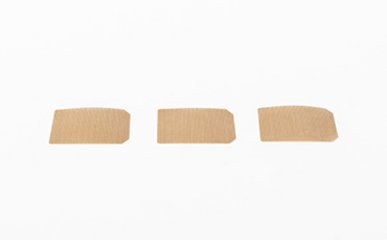

- Stamping

Stamping

Our focus in production is on stamping all non-metallic materials, especially elastomers, plastics, soft fiber materials, and many other sealing and insulation materials. All customer-specific items are tailor-made in accordance with the required dimensions, materials, and quantity.

Your contact persons

- Turning and milling

Turning and milling

We can process all standard and high-performance thermoplastics as well as elastomers using our CNC automatic lathes and milling/machining centers. This means we can cover a wide range of efficient processing methods for bars, tubes and sheets.

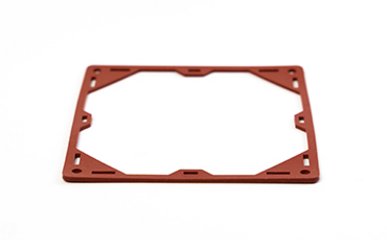

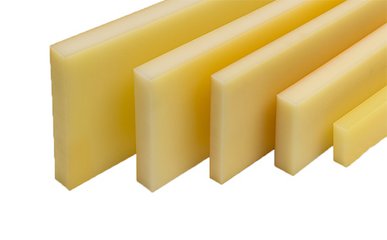

- Casting and molding

Casting and molding

Thanks to our powerful casting machines and in-house mold construction, we can offer a highly flexible range of polyurethane products – from single parts to volume production. A wide range of semi-finished products made from PUR materials is also available.

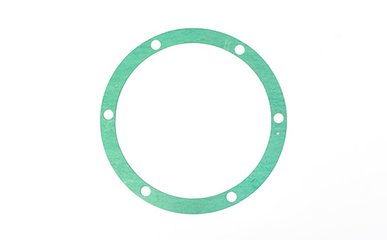

- Water-jet cutting

Water-jet cutting

Water-jet technology can be used to cut all non-metallic materials such as elastomers, plastics, all foamed materials, as well as special materials, with no deformation. Both 2D and 3D geometries can be precisely cut with zero tool costs – from prototypes to full series.

Your contact persons

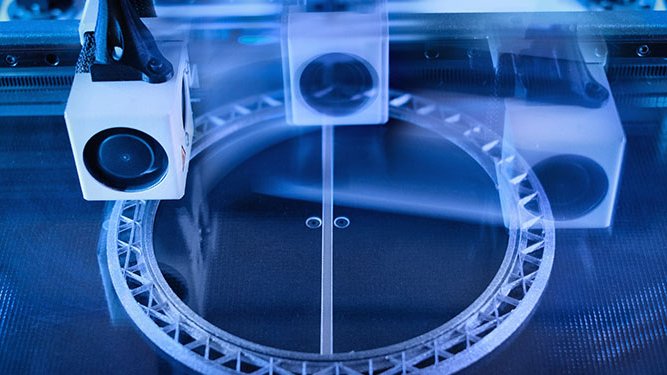

- 3D printing

3D printing

We have long since expanded our horizons beyond just prototypes and pre-series products – we now also offer series production runs for up to 50,000 pieces. We support you at every step – from adapting the design for production to any necessary finishing of the 3D-printed parts. Our comprehensive support is a unique selling point in this industry.

We now even produce parts made from the material polypropylene! For more information visit:

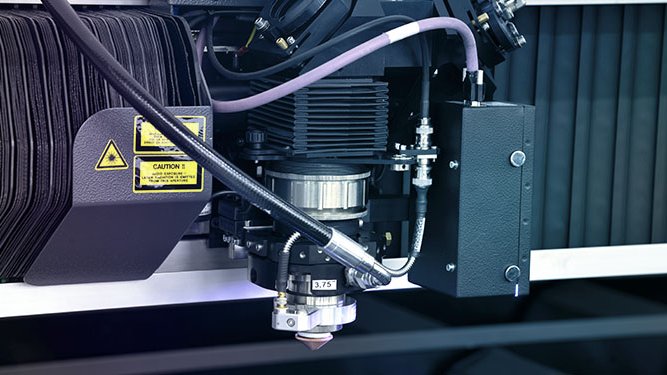

- Laser

Laser

Laser cutting is suitable for almost all non-metallic materials and ensures a high degree of flexibility without additional tooling costs. This process is ideal for the production of prototypes as well as large series volumes. In addition, the parts can be easily engraved and labeled.

- Further processing

Further processing

Besides traditional machining processes, we can produce parts using other mechanical processing methods such as cutting-off, splitting, vibratory grinding, etc. This wide range of available processes means we can produce tailored, customer-specific articles.

Manufacturing process

With our comprehensive range of machinery for rubber and plastics processing, as well as our extensive processing expertise that we have built up over decades, we can meet virtually any customer requirement.